The world's strongest rail crossing system designed for articulated dumpers, multi-axle haul trucks, and the heaviest industrial traffic.

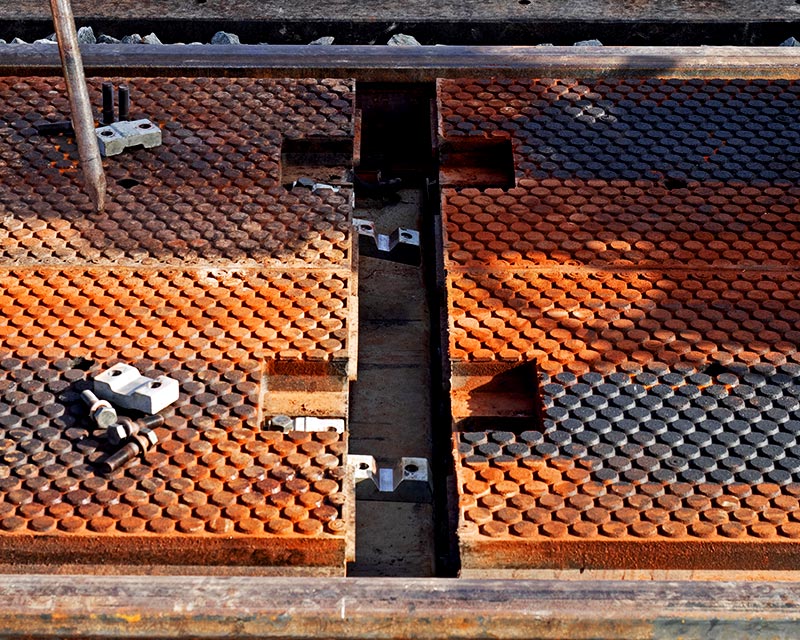

TITAN represents the pinnacle of crossing technology, combining Rosehill Rail's exclusive cold cure moulding process with unique polyurethane chemistry to create panels with the surface deflection of rubber but the strength of steel.

Individual panels are manufactured under compression to ensure dimensional stability and combat Compressive Set, preventing distortion and gapping that can compromise safety and performance in heavy-duty applications.

Designed specifically for mining, construction, and heavyweight industrial environments where standard crossing solutions simply cannot cope with the extreme loading conditions.

Revolutionary cold cure moulding process delivers unmatched performance

Handles articulated dumpers, multi-axle haul trucks, and ballast tractors in the most demanding industrial environments.

Exclusive cold cure moulding process and unique polyurethane chemistry for unparalleled durability and performance.

Manufactured under compression to prevent distortion and gapping, maintaining dimensional stability under extreme loads.

NEW moulded rubber tongue and groove connections secure against vertical lift and panel separation.

Entire crossing held in one matrix preventing accidental panel dislodging with end restraint security.

Particularly suitable for long crossings and angled road intersections requiring maximum structural integrity.

TITAN is engineered for the most extreme conditions, combining innovative manufacturing techniques with premium materials to create the ultimate heavy-duty crossing solution.

The system's unique compression manufacturing process ensures each panel maintains dimensional stability while the tongue and groove connections provide secure interlocking to prevent vertical lift under extreme loading.

Recommended installation includes Rosehill Rail's exclusive Rubber Edge Beam system with wide outer panels for maximum performance and longevity.

| TITAN Heavy Duty Specifications | |

|---|---|

| Load Capacity | Extreme heavy-duty applications |

| Manufacturing Process | Compression moulding |

| Material Technology | Cold cure polyurethane chemistry |

| Compressive Set | Anti-compressive set design |

| Connection System | Moulded tongue & groove |

| Sleeper Compatibility | 600mm centres |

| Gauge Support | All gauge types |

| Rail Compatibility | All rail types, clips, sleepers |

| Installation Method | Connector linking system |

| Tools Required | No specific tools required |

| Matrix Design | Single matrix with end restraint |

| Recommended Edge Beam | Rubber Edge Beam with wide panels |

Designed to handle the extreme loads of mining equipment including articulated dumpers and heavy haul vehicles.

Perfect for construction environments with multi-axle haul trucks and heavy machinery requiring robust crossing solutions.

Accommodates the world's heaviest traffic including ballast tractors and oversized industrial transportation.

Ideal for heavy industrial environments where standard crossing solutions cannot cope with extreme loading conditions.

Discover how TITAN can handle your most extreme industrial crossing requirements with unmatched strength and durability.