Meeting the challenge for faster train speeds with horizontal linking technology that prevents panel separation.

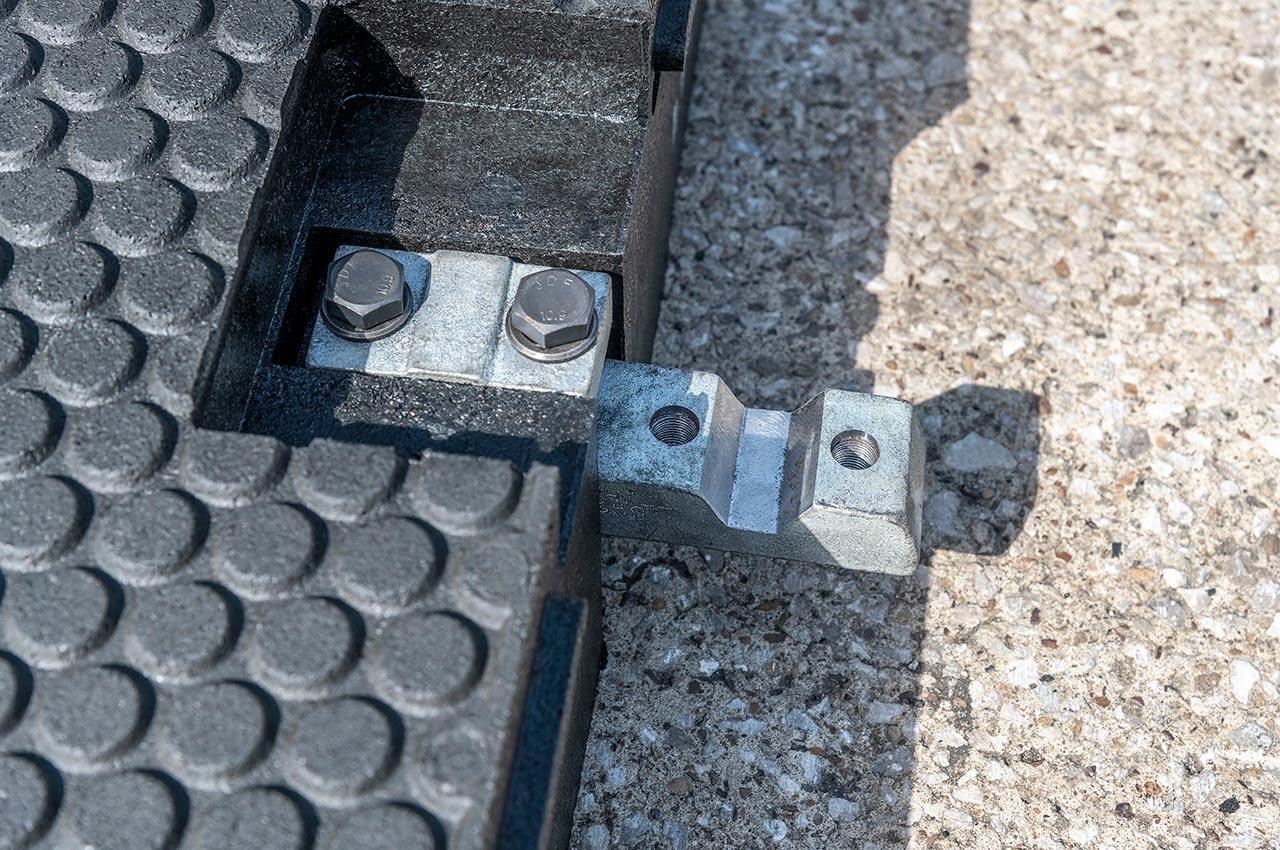

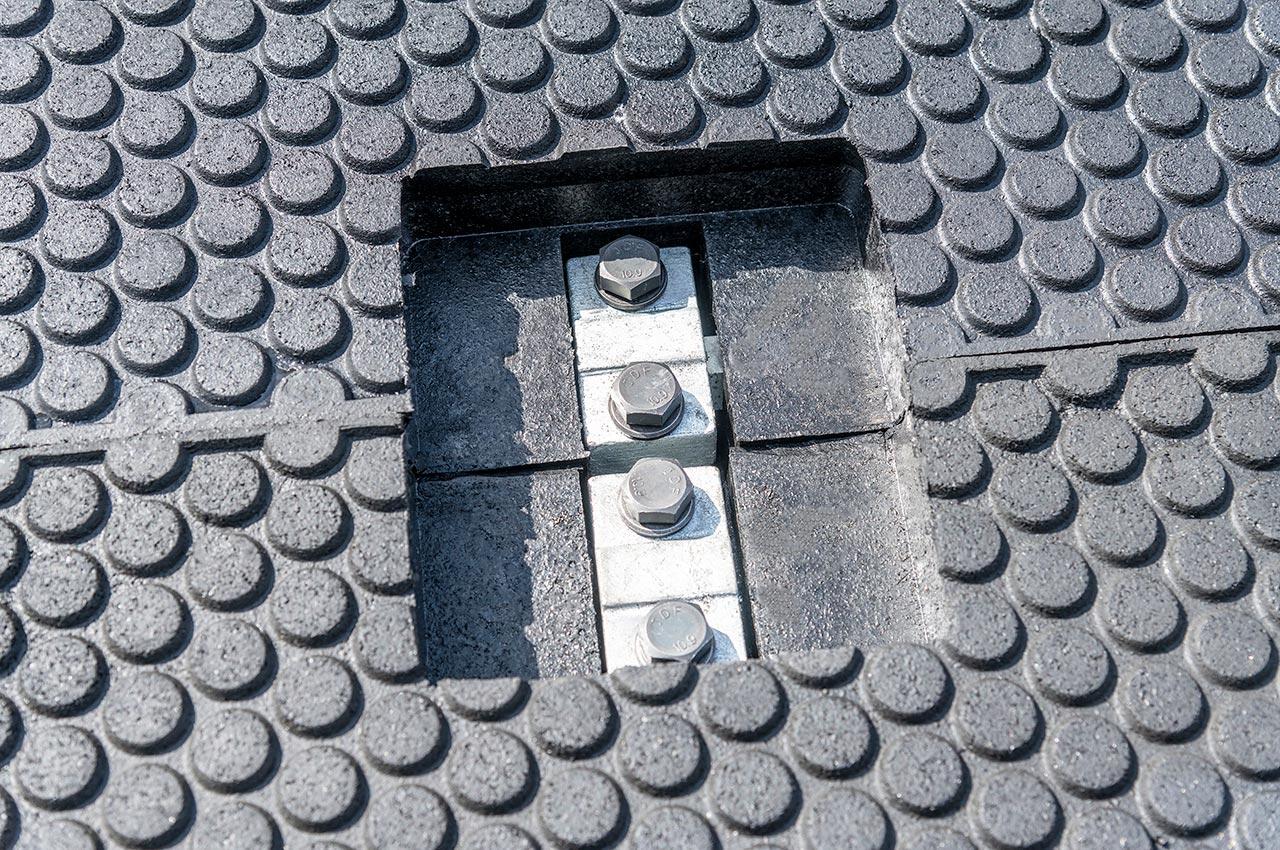

The LINK System's horizontal linking technology accommodates movement during the wave effect of differing vehicle loads applied from one panel to another, preventing separation of panels under dynamic conditions.

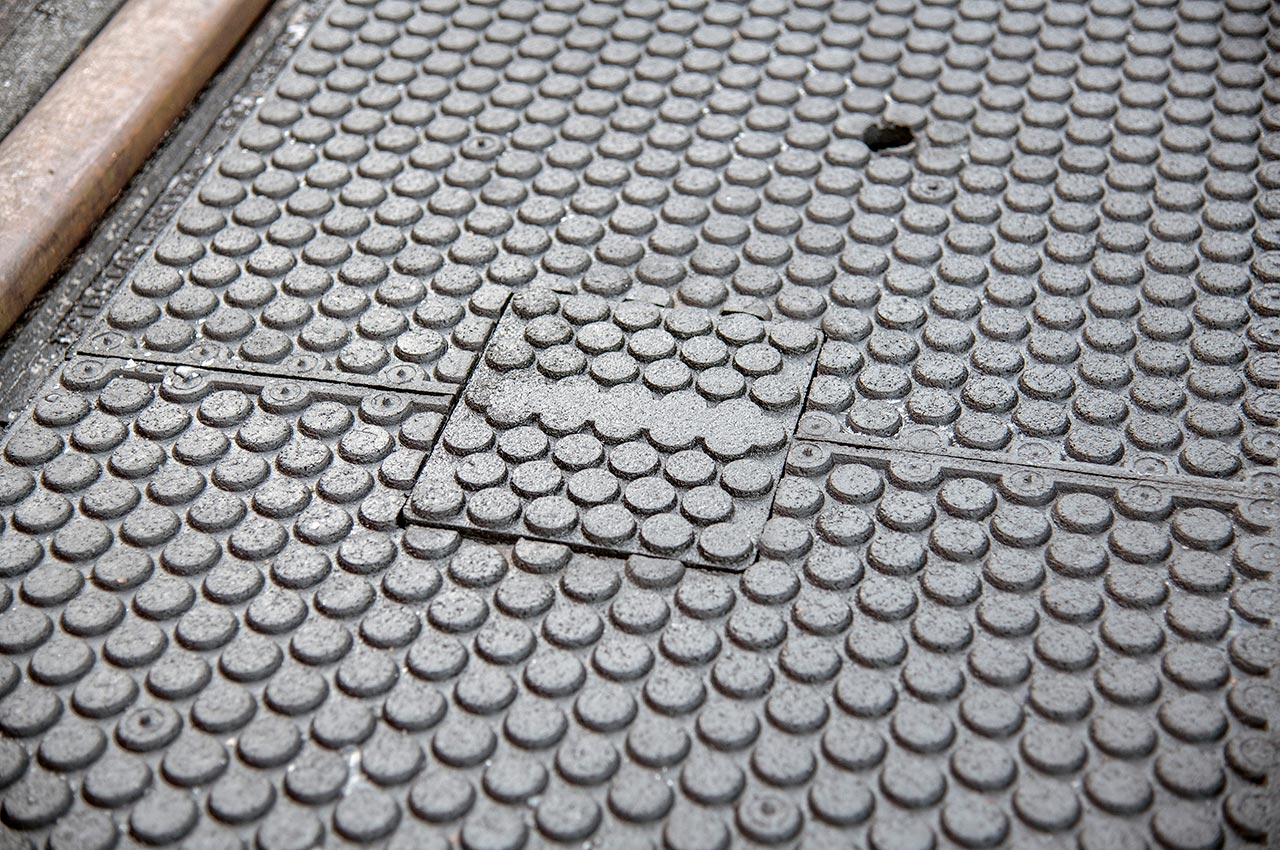

This innovative approach ensures consistent performance even when high-speed trains create varying load patterns across the crossing surface, maintaining dimensional stability and safety.

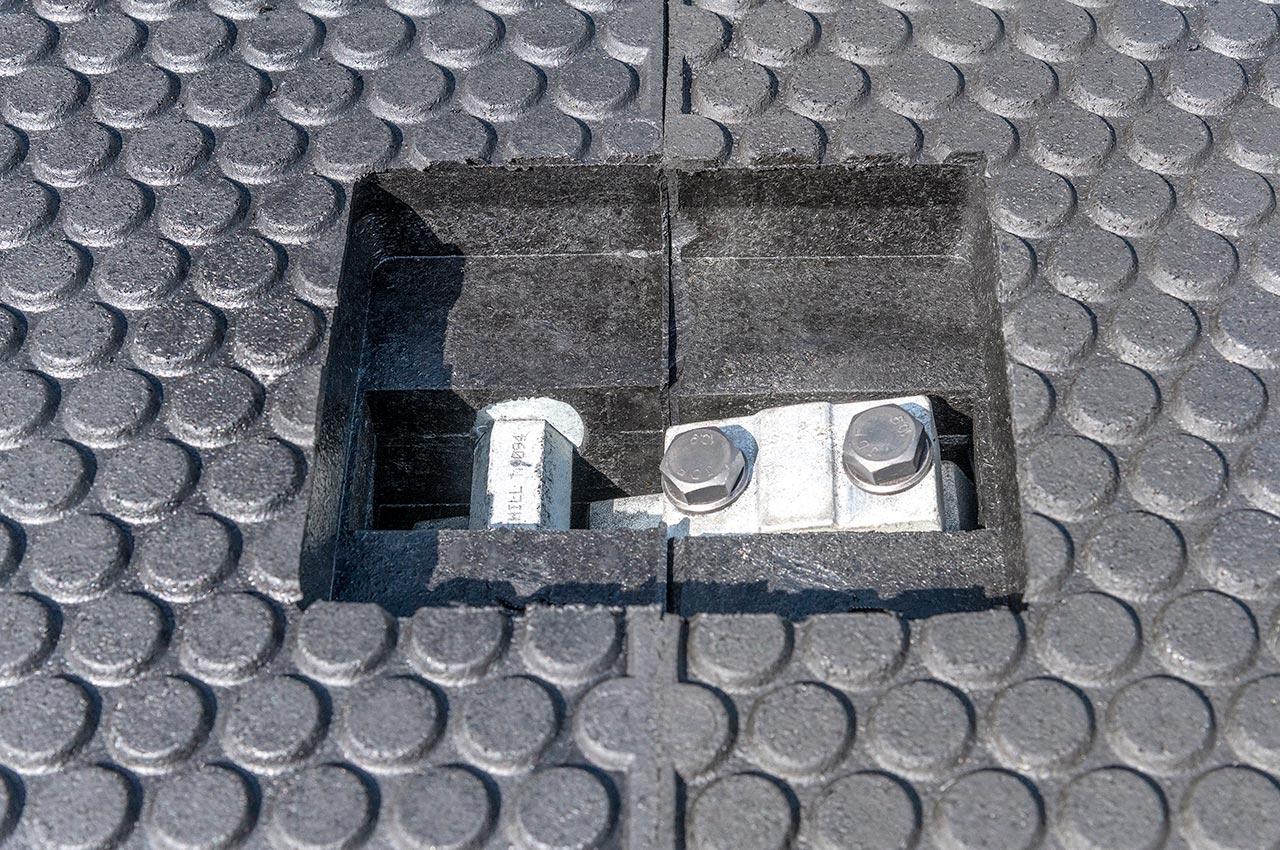

Our NEW moulded rubber tongue and groove connections provide superior panel-to-panel linking compared to traditional crossing systems.

Dynamic Load Distribution Pattern

Advanced linking system prevents vertical lift and panel separation under dynamic loading conditions.

Moulded rubber connections provide superior panel-to-panel linking and enhanced system integrity.

Sustainably manufactured in the UK from 100% recycled tyre rubber with unique polyurethane chemistry.

Specifically engineered to handle the challenges of faster train speeds and dynamic loading effects.

Full rail profile adaptability and universal gauge compatibility with 600mm sleeper centres.

Reduces installation time and minimises track possession requirements for significant cost savings.

The LINK System represents the next generation of rail crossing technology, specifically designed to meet the challenges of modern high-speed rail networks.

Each panel is compression-manufactured using our exclusive cold cure moulding process and unique polyurethane chemistry, ensuring the panels have the surface deflection of rubber but the strength required for demanding applications.

NEW moulded rubber tongue and groove connections secure against vertical lift and manage dynamic loading effects while maintaining dimensional stability.

| LINK System Specifications | |

|---|---|

| Connection Type | NEW moulded tongue & groove |

| Linking System | Horizontal linking technology |

| Manufacturing Process | Compression-manufactured panels |

| Gauge Compatibility | Universal gauge compatibility |

| Rail Profile Support | Full rail profile adaptability |

| Construction | Modular construction system |

| Sleeper Centres | Compatible with 600mm centres |

| Matrix System | Single matrix containment |

| Material Origin | UK manufactured, 100% recycled |

Specifically designed to handle the dynamic loads and wave effects created by high-speed train operations.

Perfect for busy urban crossings where consistent performance under varying load conditions is critical.

Ideal for crossings experiencing variable loading patterns that require advanced panel linking technology.

Excellent for upgrading existing crossings to handle increased speeds and improved safety standards.

Discover how the LINK System can enhance your rail network's performance with advanced wave effect management and superior panel linking technology.